- 8 Posts

- 41 Comments

Thanks for the other tips. I’ve tried a cold pole with the last filament to see if we could get anything out of there and I think we should be good, but you never really know.

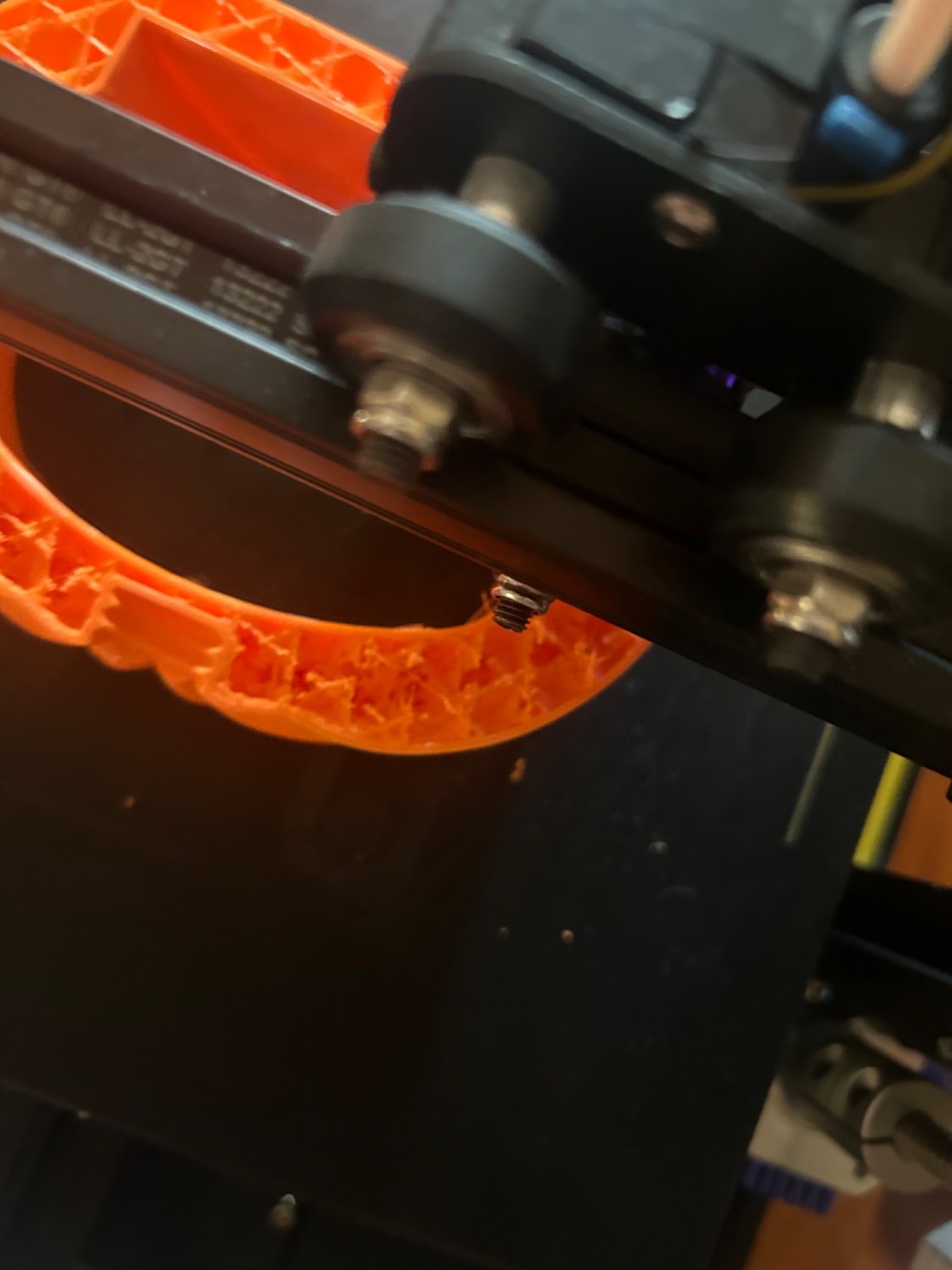

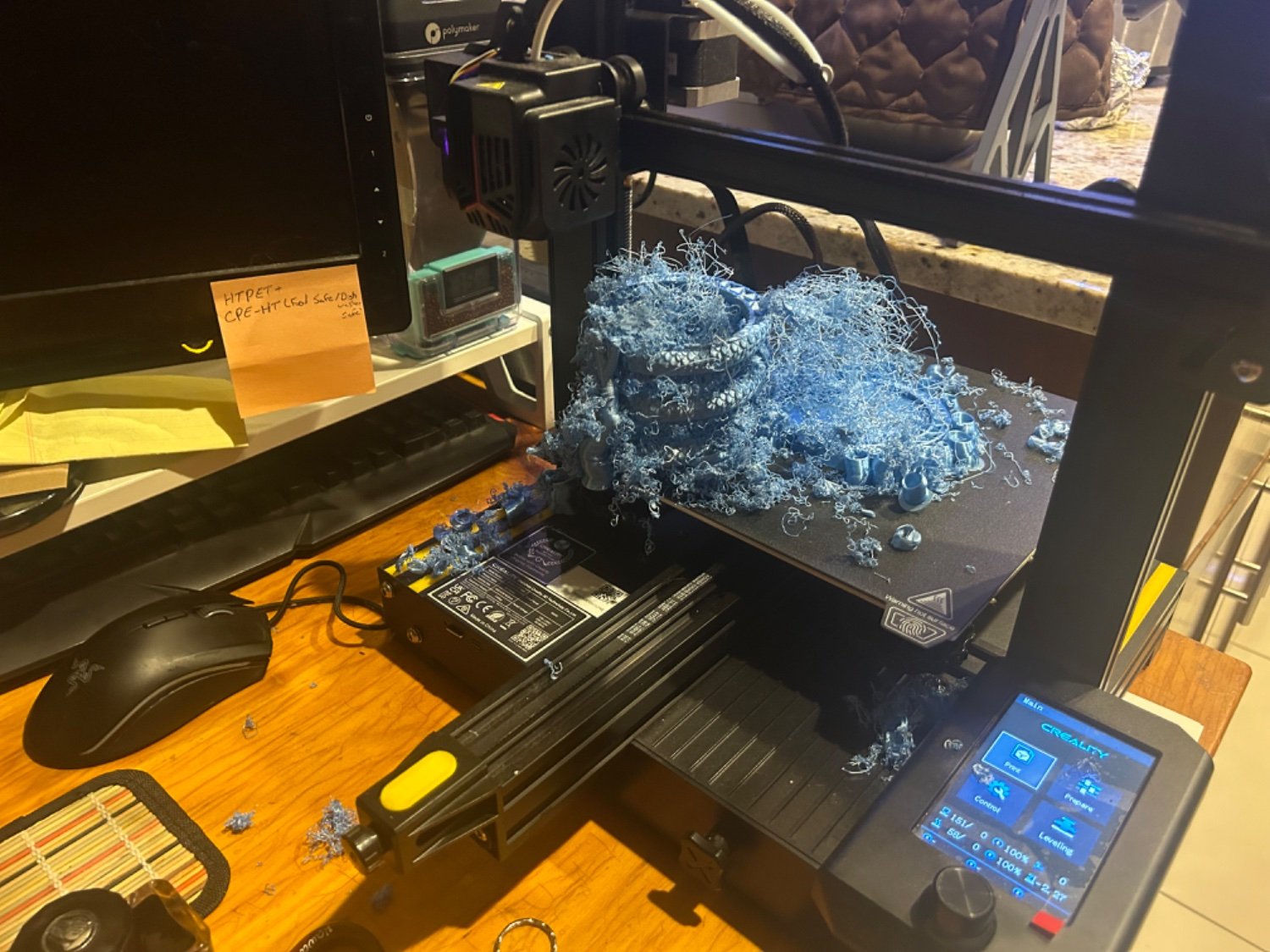

As far as the rest of it, it seems to be happening with every filament I slice in Prusa slicer.

This was a brand new filament I had opened from Micro Center, it’s just their generic inland filament and it looks like the humidity in my dry box is about 16% after running it through my dryer. Maybe it’s too dry lol.

To be honest, I didn’t think about replacing the nozzle that’s probably a good idea. I got this printer from an auction site used so I can only imagine it’s the original nozzle from who knows how long ago

- @Koopa_Khan@lemmy.world to

English

English - •

- lemmy.world

- •

- 14d

- •

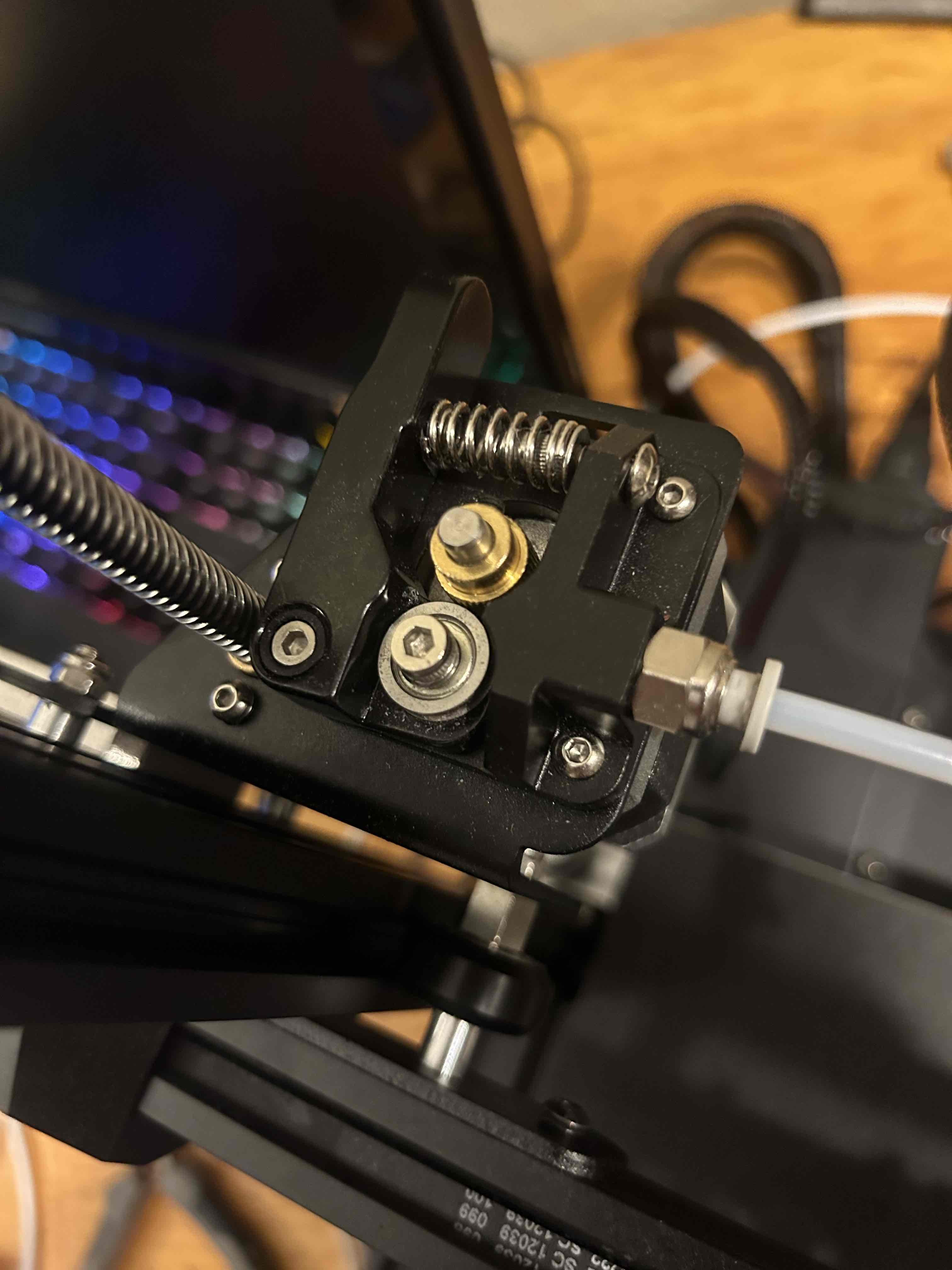

Of course! This should be the original link. I think my issue was slightly different, but hopefully this helps. My stepper motors were over heating and skipping steps. If it looks like that might solve your issue, this article helped with my ender 3

Thank you! I appreciate it!

- @Koopa_Khan@lemmy.world to

English

English - •

- lemmy.world

- •

- 21d

- •

- @Koopa_Khan@lemmy.world to

English

English - •

- lemmy.world

- •

- 1M

- •

- @Koopa_Khan@lemmy.world to

English

English - •

- 10M

- •

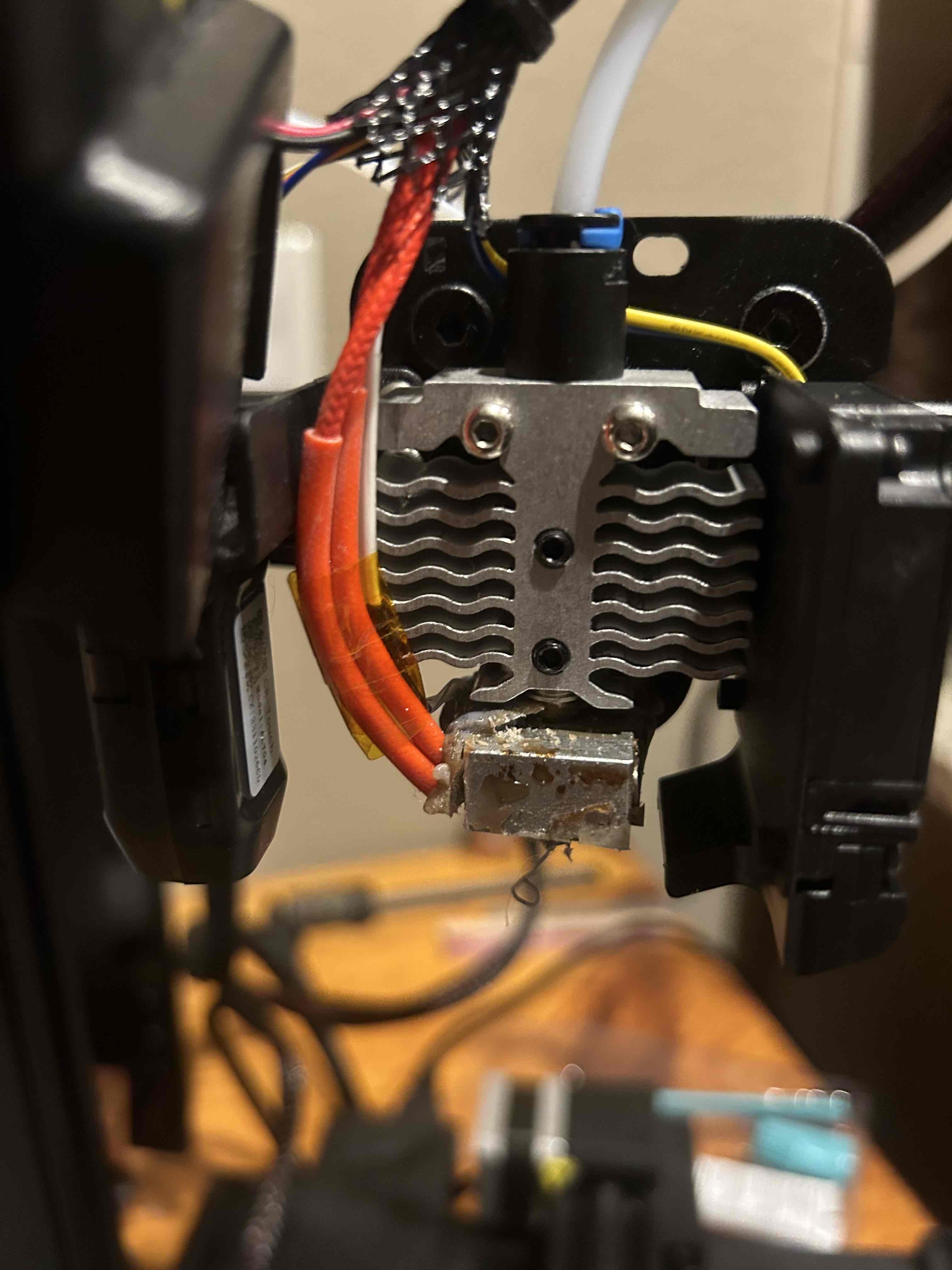

No worries! Thats exactly where it is. The burned on stuff goes all the way down the side and around the back.

I’m afraid this bing need to be totally taken apart but i haven’t done much more than investigate and pull at some easy pieces so far.

Keep in mind this is my first printer and I’m new to the hobby so I’m at the why isn’t this working and why did I do this to myself stage. This might not be a problem for more experienced people. Thankfully this community exists because I’d be lost otherwise

The problem is I don’t even know what happened or how the pla got around that silicon sleeve. Part of me just wants to say forget it and continue to print with it like this but I feel like this is just a fire waiting to happen.

Thank you for the advice! I think I’m gonna run with it and put the printer in the closet for a bit.

- @Koopa_Khan@lemmy.world to

English

English - •

- lemmy.world

- •

- 10M

- •

It looks like I can’t extrude in the air either. Maybe I didn’t get all the gunk out of the nozzle the first time I’m just clueless on how to. I tried soaking it and acetone and digging stuff out and that didn’t seem to do it and the only pen I have doesn’t go through the hole in the nozzle. It’s too thick. It’s sitting at about 240 right now so I’m hoping That it just melts I guess.

At this point, I’m wondering if it’s not just worth buying a new nozzle and calling it a day

- @Koopa_Khan@lemmy.world to

English

English - •

- lemmy.world

- •

- 1Y

- •

Not yet, I’ve only ever printed PLA and heard that it will never get water tight. Grant it, I have a print I can test when it finishes up in a day or two.

I thought about running multi-material but would need to get that add on that can splice in filaments to run through the Neo’s single extruder ( maybe the sidewinder x1?), but can’t remember what it’s called to look at reviews

Ultimately I’m printing a lot of MTG commander deck boxs with screw tops and would like them to include a seal so their water tight. I’m also starting to design some camera adapters that need to set outside for a lengthy period of time.

I got lucky with mine since neo came with an all metal hot end but haven’t done any upgrades. Long term I was pretty much just planning to use this one until it stops printing, but now this is a full blown addiction and I’m hoping to get a second printer with multiple hot ends when my wife and I get get some more space.

Thank you for the ASA tips! Do you have any recommendations on printing that material? I think I overlooked that filament.

- @Koopa_Khan@lemmy.world to

English

English - •

- 1Y

- •

- @Koopa_Khan@lemmy.world to

English

English - •

- 1Y

- •

Thank you for the tip! I just checked, it looks like it was disabled so that wasn’t my issue. I wonder why it was causing you issues though